All Lots Must Go! Large Quantity of Welding Wire & Electrodes

- LOT 1

![site]()

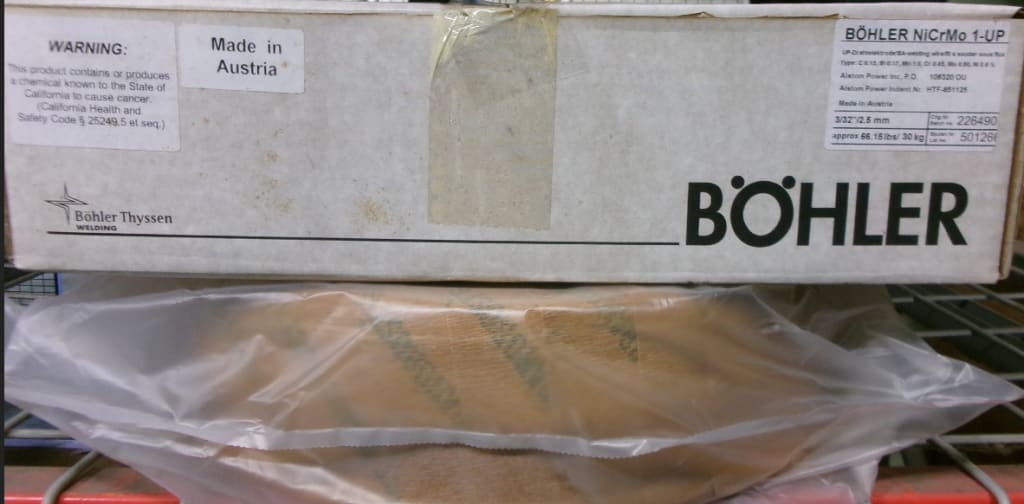

Approximate: 11,960# of Assorted Weld Wire for Nickel-Chromium-Molybdenum Alloy for Submerged Arc Welding Aplication

Approximate: 11,960# of Assorted Weld Wire for Nickel-Chromium-Molybdenum Alloy for Submerged Arc Welding Aplication Including: NICRMO1 UP-2.5 SS, WELD WIRE NICRMO1 - 2.5MM 2693#,Weld Wire for Nickel-Chromium-Molybdenum Alloy for Submerged Arc Welding Application, NICRMO1 UP-3.0 SS, WELD WIRE NICRMO1 - 3.0MM 2067#,Weld Wire for Nickel-Chromium-Molybdenum Alloy for Submerged Arc Welding Application, NICRMO2.5 UP-3.0SS, WELD WIRE NICRMO2.5 - 3.0MM SML SPOOL 522#,Weld Wire for Nickel-Chromium-Molybdenum Alloy for Submerged Arc Welding Application, NICRMO2.5 UP-3.0SS, WELD WIRE NICRMO2.5 - 3.0MM SML SPOOL 517.5#,Weld Wire for Nickel-Chromium-Molybdenum Alloy for Submerged Arc Welding Application, S2NICRMO1-3.2 SS, WELD WIRE S2CRMO1 - 3.2MM 5005#,Weld Wire for Low-Alloy Steel for Submerged Arc Welding Application, S3NICRMO-2.5-2.4SS, WELD WIRE S3NICRMO-2.5 2.4MM SML SPOOL 1155#,Weld Wire for Nickel-Chromium-Molybdenum Alloy for Submerged Arc Welding Application - LOT 2

![site]()

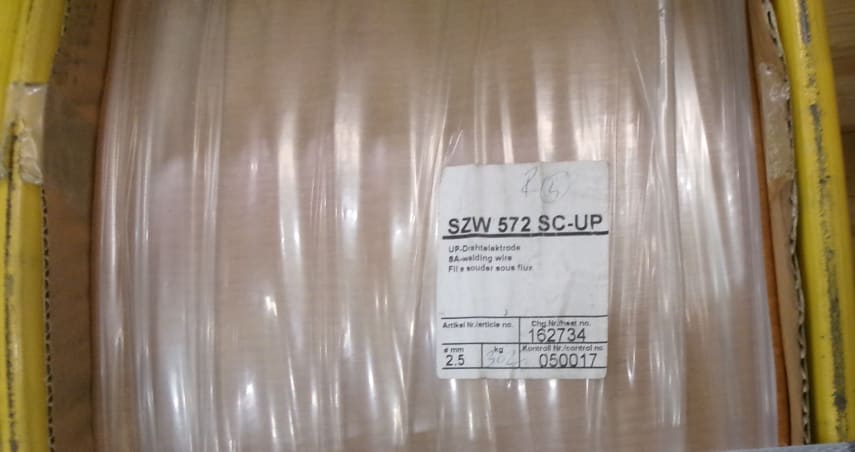

Approximate: 4,162# of Assorted Stainless Steel Weld Wire for Submerged Arc Welding Application

Approximate: 4,162# of Assorted Stainless Steel Weld Wire for Submerged Arc Welding Application Including: SZW572SC UP-1.6 SS, WELD WIRE - 1.6MM 554.4#,Stainless Steel Weld Wire for Sub Arc Welding Application, SZW572SC UP-2.5 LS, WELD WIRE - 2.5MM 3246#,Stainless Steel Weld Wire for Sub Arc Welding Application, SZW572SC UP-2.5 LS, WELD WIRE - 2.5MM 96#,Stainless Steel Weld Wire for Sub Arc Welding Application, SZW572SC UP-3.0 LS, WELD WIRE - 3.0MM 123#,Stainless Steel Weld Wire for Sub Arc Welding Application, SZW572SC UP-3.0 LS, WELD WIRE - 3.0MM 75#,Stainless Steel Weld Wire for Sub Arc Welding Application, SZW572SC UP-3.0 LS, WELD WIRE - 3.0MM 68#,Stainless Steel Weld Wire for Sub Arc Welding Application - LOT 3

![site]()

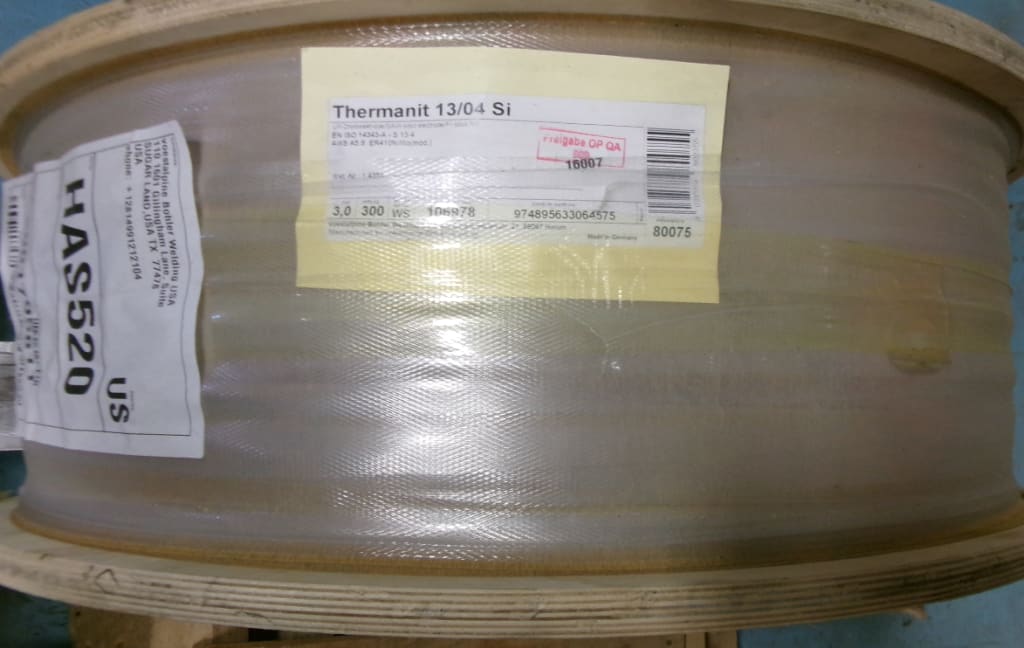

Approximate: 11,362# of Assorted Low Alloy Steel for Sub Arc Welding Application

Approximate: 11,362# of Assorted Low Alloy Steel for Sub Arc Welding Application Including: EB3-1/8 SS, "WELD WIRE LAS - 1/8""" 1480#,Low Alloy Steel for Sub Arc Welding Application, EB3-3/32 SS, "WELD WIRE LAS - 3/32""" 110#,Low Alloy Steel for Sub Arc Welding Application, 20MVW UP-2.5 LS, WELD WIRE 12CR - 2.5MM LRG SPOOL 1768#,Low-Alloy Welding Wire for Sub Arc Welding Application, 20MVW UP-2.5 LS, WELD WIRE 12CR - 2.5MM LRG SPOOL 65#,Low-Alloy Welding Wire for Sub Arc Welding Application, 20MVW UP-2.5 SS, WELD WIRE 12CR - 2.5MM SML SPOOL 259#,Low-Alloy Welding Wire for Sub Arc Welding Application, 20MVW UP-3.0 LS, WELD WIRE 12CR - 3.0MM LRG SPOOL 2899#,Low-Alloy Welding Wire for Sub Arc Welding Application, 20MVW UP-3.0 LS, WELD WIRE 12CR - 3.0MM LRG SPOOL 2251#,Low-Alloy Welding Wire for Sub Arc Welding Application, BF16, FLUX BF16 2090#,Low-alloy and martensitic stainless steel for Sub Arc Welding Application, BF16, FLUX BF16 440#,Low-alloy and martensitic stainless steel for Sub Arc Welding Application - LOT 4

![site]()

Approximate: 17,578# of Assorted High-Strength Low-Alloy for Sub Arc Welding Aplication

Approximate: 17,578# of Assorted High-Strength Low-Alloy for Sub Arc Welding Aplication Including: 3NICRMO 2.5UP3.0LS, WELD WIRE 3NICRMO 2.5-UP 3.0MM LRG SPOOL 11139#,High-Strength Low-Alloy for Sub Arc Welding Application, 3NICRMO 2.5UP3.0SS, WELD WIRE 3NICRMO 2.5-UP 3.0MM SML SPOOL 298#,High-Strength Low-Alloy for Sub Arc Welding Application, ER410NIMO-2.5 LS, WELD WIRE 12CR - 2.5MM 6141#,Low-Carbon Martenstic Stainless Steel Welding Wire - LOT 5

![site]()

Approximate: 28,160# of Assorted Stainless Steel and Nickel Alloy for Sub Arc Welding Application

Approximate: 28,160# of Assorted Stainless Steel and Nickel Alloy for Sub Arc Welding Application Including: WP330, FLUX WP330 1265#,stainless steels and nickel alloy for Sub Arc Welding Application, WP380, FLUX WP380 15015#,stainless steels and nickel alloy for Sub Arc Welding Application, WP380, FLUX WP380 9900#,stainless steels and nickel alloy for Sub Arc Welding Application, WP380, FLUX WP380 1980#,stainless steels and nickel alloy for Sub Arc Welding Application - LOT 6

![site]()

Approximate: 3,724# of Assorted Stainless Steel Welding Wire

Approximate: 3,724# of Assorted Stainless Steel Welding Wire Including: ER90S-B3-1/16 X 36, ""WELD WIRE ER90S-B3 - 1/16""""X36"""" 50#,Ferritic stainless steel, ER90S-B3-0.045X36, ""WELD WIRE ER90S-B3-0.045""""X36"""" 30#,Ferritic stainless steel, ER90S-B3-0.045X36, ""WELD WIRE ER90S-B3-0.045""""X36"""" 20#,Ferritic stainless steel, ER90S-B3-0.045X36, ""WELD WIRE ER90S-B3-0.045""""X36"""" 10#,Ferritic stainless steel, ER410NIMO-3.0 LS, WELD WIRE 12CR - 3.0MM 2899#,Stainless Steel Welding Wire, ER410NIMO-3.0 SS, WELD WIRE 12CR - 3.0MM 264#,Stainless Steel Welding Wire, SZW44 UP-2.5 SS, WELD WIRE 5CR - 2.5MM 110#,Stainless Steel Weld Wire for Sub Arc Welding Application, SZW44 UP-3.0 LS, WELD WIRE 5CR - 3.0MM 341#,Stainless Steel Weld Wire for Sub Arc Welding Application - LOT 7

![site]()

Approximate: (88) & 23.8# of Harfacing Welding Electrode

Approximate: (88) & 23.8# of Harfacing Welding Electrode Including: ZN 403494P0200, WELDING ELECTRODE D2.00 UTP 068 HH 23.8#,Hardfacing Welding Electrode, HZN 403494P0250, WELDING ELECTRODE D2.50 UTP 068 HH 4.003#,Hardfacing Welding Electrode, HZN 403494P0320, WELDING ELECTRODE D3.25 UTP 068 HH 72.056#,Hardfacing Welding Electrode, HZN 403494P0320, WELDING ELECTRODE D3.25 UTP 068 HH 11.988#,Hardfacing Welding Electrode

Essential Information

General Information

- Auction Dates

- Starts: 06 January 2026 at 14:00 GMTEnds: 12 February 2026 at 18:00 GMT

- Site Address

- 1200 Willis RoadRichmondVA23237United States

- Viewing Days

- By Appointment OnlyContact Us to Schedule an Inspection Appointment

Fees & Payment

- Currency

- USD

- Buyers Premium

- 18% or as specified on individual items

- Payment

General payment information

Payment is due immediately upon receipt of the invoice.

• All payments must be made in the currency stated on the invoice.

Payment Terms

• Company Checks up to $3,000 USD

• Certified Checks over $3,000 USD

• Wire Transfer

• Money orders or cash will not be accepted.

• Credit Cards (3% Processing Fee will be Applied) (Call +1 631-418-8261 for CC Payment)

No payments will be accepted on-site; all payments need to be mailed to our office

Please make checks payable to

Apex Auctions USA

315 Walt Whitman RoadHuntington Station, NY 11746

Suite 207

Goods

- Clearance days

- 16 February 2026 at 13:00 GMT - 27 February 2026 at 21:00 GMTBy Appointment Only

- General Collection Information

Collection

Buyers are fully responsible for the removal of items plus all shipping and rigging charges.

• Due to insurance regulations Apex will not supply a forklift, or other motorized rigging equipment to support loading, packaging, or shipping, unless specifically posted.

• Items are only available to collect once the transferred funds have cleared and a collection appointment has been booked.

• Buyers or third-party movers must present an invoice to the on-site personnel when removing their items.

• Buyers must complete the removal of items within the clearance deadline. Unless otherwise stated, normal removal hours are Monday through Friday, 9 a.m. to 4 p.m. (local time).

• Contact and removal information will be emailed at the time invoices are issued

- Sales Contacts

- Auction informationMathew Koster315 Walt Whitman Road

Huntington Station

NY

11746

United States mkoster@apex-group.com+1(631) 418-8850